Varitron RAM-H Series High Precision Hollow Shaft Spiral Bevel Gearbox

- High Precision Gear -

The planetary gear and sun gear are manufactured from high quality Ni-Cr-Mo alloy steel. Precision machined and carburized, then for precision tooth grinding or skiving assures gears high precision.

- Modular Deisgn of Motor Connection Plate -

The special modular design of motor connection plate is suitable for any brand and any type of servomotor. Manufactured from aluminum alloy, its surface is anodized treated for upgrading environmental-resistant and corrosion-resistant capability.

- Single-piece Gearbox & Advanced Surface Treatment -

The gearbox and internal gear ring are single price design and constructed, which is manufactured from Cr-Mo alloy steel, and tempered for high torque output. Gearbox surface is anti-corrosive treated for upgrading environmental resistant and corrosionresistant capability.

- Modular Input Shaft -

Modular input shaft design and motor shaft are coupled through a dynamic balanced collar clamping mechanism to ensure connection concentricity and zero slip power transmission at high speed.

- Integrated Planetary Arm Bracket -

The planetary arm bracket and the output shaft are single piece design constructed to increase torsional rigidity and accuracy. The entire structure is one-time machined for controlling accuracy in the specified tolerance.

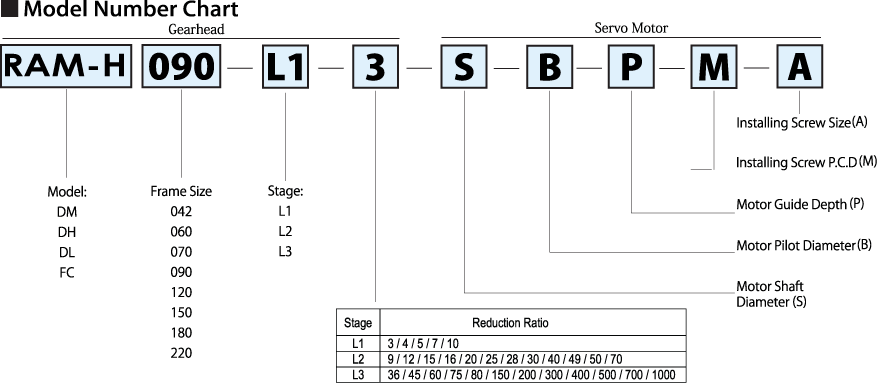

Model Number | RAM-H Series Hollow Shaft Right Angle Spiral Bevel Gearbox |

Speed Reduction Method | Planetary gear mechanism with designed tooth profile |

Efficiency | 95% per stage gearbox |

Shock Load | 300% as there are only compressive forces rather than shear forces on the tooth |

Gear box Mounting | Flange Mounting, Foot mounting parts sold separately |

Reduction Ratio | Up to 1:10 per stage 1:1000 on 3-stages |

Capacity Range | 100Watt to 11,000Watt |

Enclosure | Totally enclosed IP55 |

Power Source | Servo motor, stepper motor |

Backlash | Single Stage: below 5arcmin Double Stages: Below 8arcmin |

Reduction Gearbox Lubrication Method | High viscosity anti-separation grease |

Method of Coupling with Driven Machine | Coupling, gears, chain sprocket or belt |

Standard | CE, UL, CSA, ISO 9001, ISO14001 |

Warranty | 1 Year Limited Warranty |

Technical

Information

|

Specification 規格 |

Ratio減速比 (Stage 段數) |

RAM060 |

RAM090 |

RAM120 |

RAM150 |

|

Instantaneous Max. Output Torque 瞬間最大輸出扭矩 T2B (Nm) |

3/9/10/30/100 |

132 |

498 |

750 |

1428 |

|

4/12/16/20/28/40 |

162 |

498 |

750 |

1500 |

|

|

5/15/25/35/50 |

138 |

498 |

750 |

1500 |

|

|

7/21/49/70 |

144 |

498 |

750 |

1500 |

|

|

Defined Output Torque 額定輸出扭矩 T2N (Nm) |

3/9/10/21/30 |

44 |

166 |

250 |

476 |

|

4/15/16/20/25/28/40 |

54 |

166 |

250 |

500 |

|

|

5/15/25/35/50 |

46 |

166 |

250 |

500 |

|

|

7/21/49/70 |

48 |

166 |

250 |

500 |

|

|

Reduction Ratio 減速比 |

L1: 1 Stage 單段 |

3 / 4 / 5 / 7 / 10 |

|||

|

L2: 2 Stage 雙段 |

9 / 12 / 15 / 16 / 20 / 21 / 25 / 28 / 30 / 35 / 40 / 49 / 50 / 70 / 100 |

||||

|

L3: 3Stage 三段 |

100/200/250 |

||||

|

Defined Input Rotational Speed 額定輸入轉速 n1N (rpm) |

3/4/5 (L1) |

3300 |

2600 |

2300 |

2200 |

|

7/10 (L2) |

4000 |

2900 |

2700 |

2700 |

|

|

12 ~ 40 (L2) |

4400 |

3200 |

3000 |

3000 |

|

|

50 (L2) |

4800 |

3600 |

3300 |

3200 |

|

|

70 ~ 100 (L2) |

5500 |

4200 |

3900 |

3500 |

|

|

Backlash 精密背隙 (arcmin) |

3~10 (L1) |

≤8 |

≤8 |

≤8 |

≤8 |

|

12~100 (L2) |

≤11 |

≤11 |

≤11 |

≤11 |

|

|

Full Load Efficiency 滿載時使用效率 % |

3~10 (L1) |

≥91 |

|||

|

12~100 (L2) |

≥88 |

||||

|

Service Life使用壽命Lh2 (hrs) |

3~100 (L1,L2) |

20000 |

|||

|

Weight 重量 (kgs) |

3~10 (L1) |

Vary according to shaft type 依產品輸出軸類型有所不同 |

|||

|

12~100 (L2) |

|||||

|

Noise 噪音值 (db) |

|

65 |

65 |

65 |

65 |

|

Temperature使用溫度範圍°C |

|

(-15°C ~ +90°C |

|||

|

Protection Rank 防護等級 |

|

IP64 |

|||

|

Lubricating Oil 潤滑油 |

|

Synthetic Lubricant 合成潤滑油 ISO VG220 |

|||

Designation

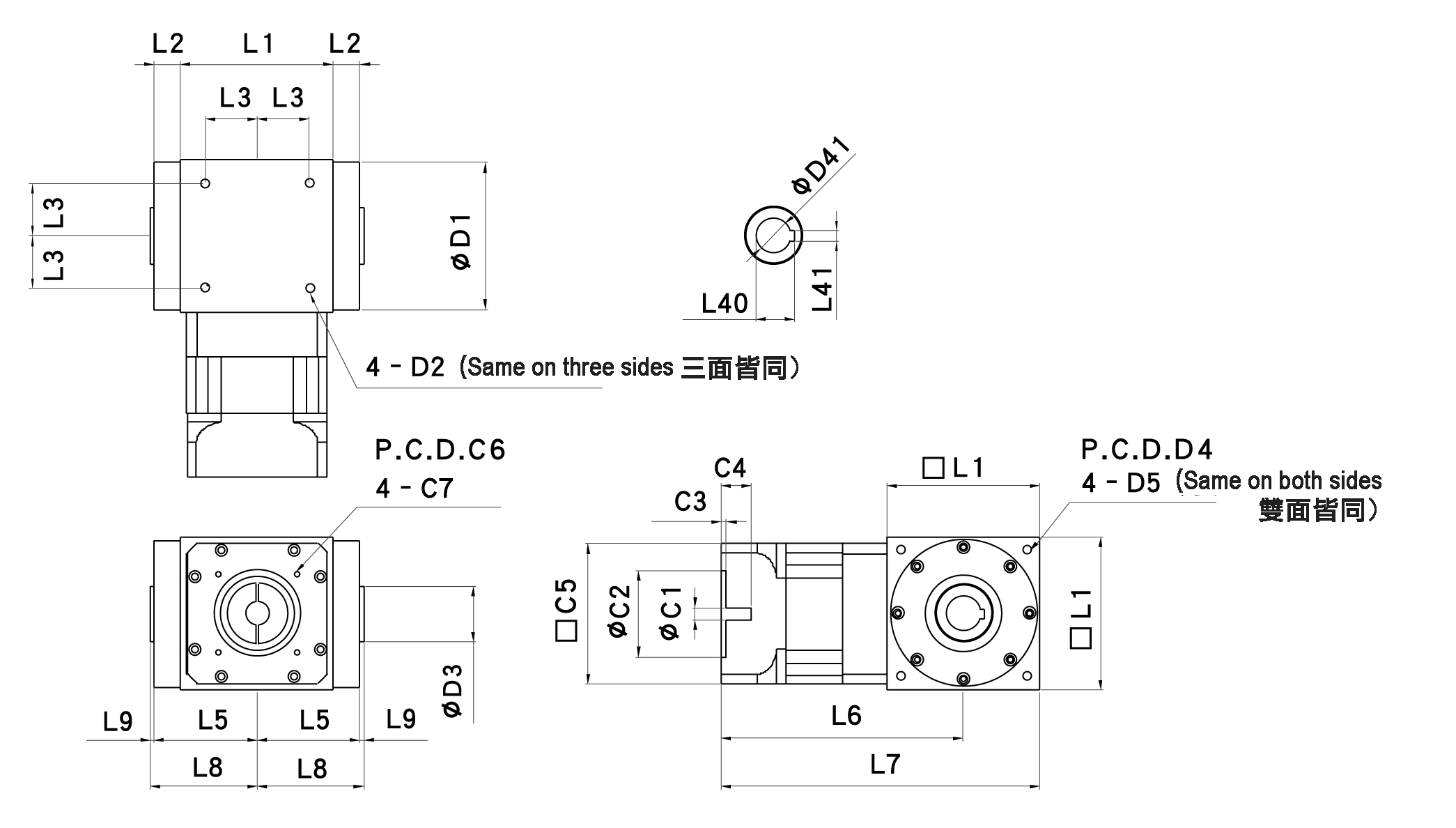

Dimensions | RAM060H | RAM090H | RAM120H | RAM150H |

L1 | 83 | 114 | 124 | 154 |

L2 | 17 | 21.5 | 21.5 | 21 |

L3 | 28.284 | 33.587 | 42.426 | 45.962 |

L5 | 58.5 | 78.5 | 83.5 | 98 |

L6(1 Stage) | 146 | 188 | 196 | 285 |

L6(2 Stage) | 168 | 216 | 224 | 335 |

L7(1 Stage) | 187.5 | 245 | 258 | 362 |

L7(2 Stage) | 209.5 | 273 | 286 | 412 |

L8 | 59.5 | 79.5 | 84.5 | 99 |

L9 | 1 | 1 | 1 | 1 |

L40 | 16.3 | 22.8 | 31.3 | 43.3 |

L41 | 5 | 6 | 8 | 12 |

D1 | 79 | 109 | 119 | 139 |

D2 | M5*P0.8x10 | M6*P1.0x14 | M8*P1.25x18 | M10*P1.5x22 |

D3 | 42 | 62 | 85 | 90 |

D4 | 100 | 130 | 145 | 165 |

D5 | M5*P0.8x10 | M6*P1.0x14 | M8*P1.25x18 | M10*P1.5x22 |

D41 | 14 | 20 | 28 | 40 |

C1 | ≤14 | ≤24 | ≤28 | ≤42 |

C2 | 30-50 | 50-80 | 55-110 | 95-130 |

C3 | 6 | 6 | 5 | 10 |

C4 | ≤35 | ≤47.5 | ≤47.5 | ≤66.5 |

C5 | 60 | 95 | 114 | 142 |

C6 | 70 | 90 | 130 | 145 |

C7 | M5 | M6 | M8 | M8 |